We deliver high-quality undercarriage parts and solutions for your construction and mining equipment, offering everything from idlers and sprockets to complete track assemblies with expert support.

Explore our featured selection of premium undercarriage parts, including idlers, sprockets, track rollers, carrier rollers, and track chain assemblies designed for optimal performance and durability.

Our precision-engineered idlers deliver smooth track operation and maximum durability, ensuring perfect fit and extended service life across all major construction and mining equipment brands.

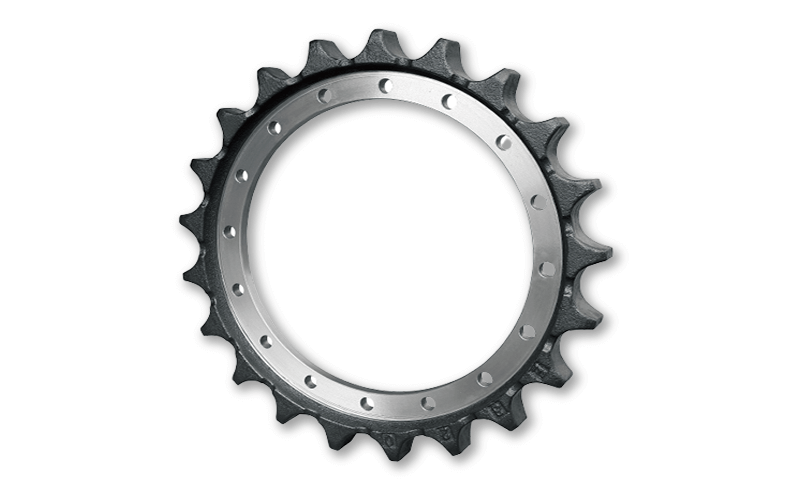

Our sprockets are engineered with hardened steel and precise tooth geometry, guaranteeing optimal track drive and wear resistance for construction and mining machinery worldwide.

Our premium carrier rollers feature advanced sealing systems and precision engineering, maximizing equipment uptime while reducing maintenance costs in challenging applications.

Engineered for excellence, these premium track rollers deliver superior durability and smooth operation with advanced sealing technology and precision bearings.

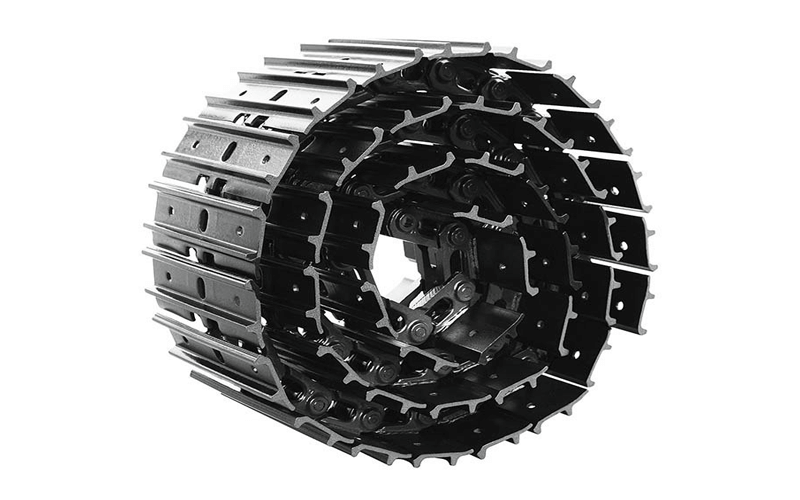

Advanced track chain assemblies combine hardened components and precise tolerances, ensuring optimal power transfer and extended service life in heavy-duty applications.

High-grade track plates with matching bolts and nuts ensure optimal track assembly integrity, engineered with premium materials and exact tolerances for reliable performance.

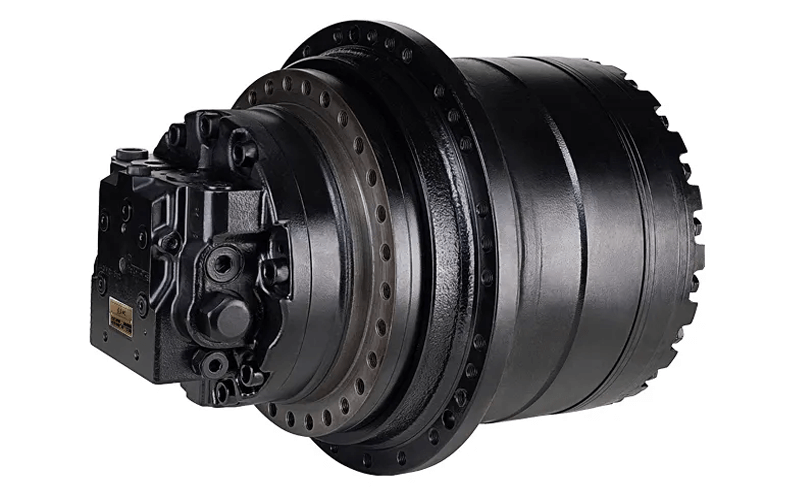

Professional-grade hydraulic motors integrate advanced engineering and premium components, guaranteeing stable power transmission and extended service life.

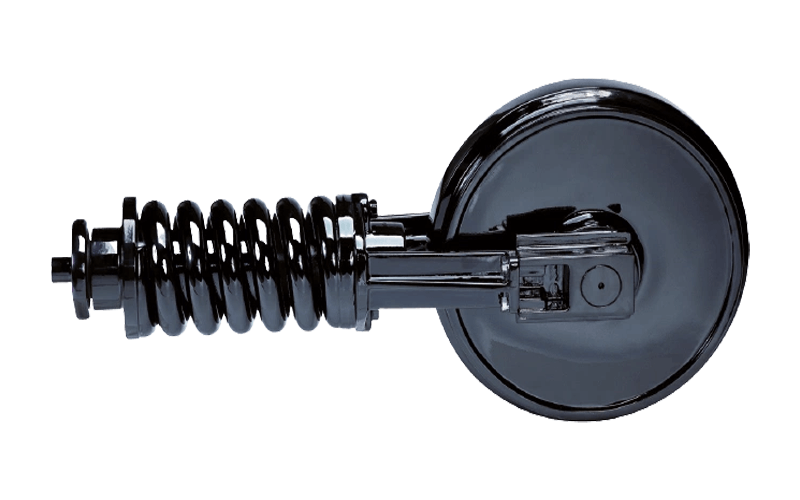

High-performance track tensioners combine spring-loaded mechanisms and sealed components, ensuring consistent tension control and maximum durability in harsh environments.

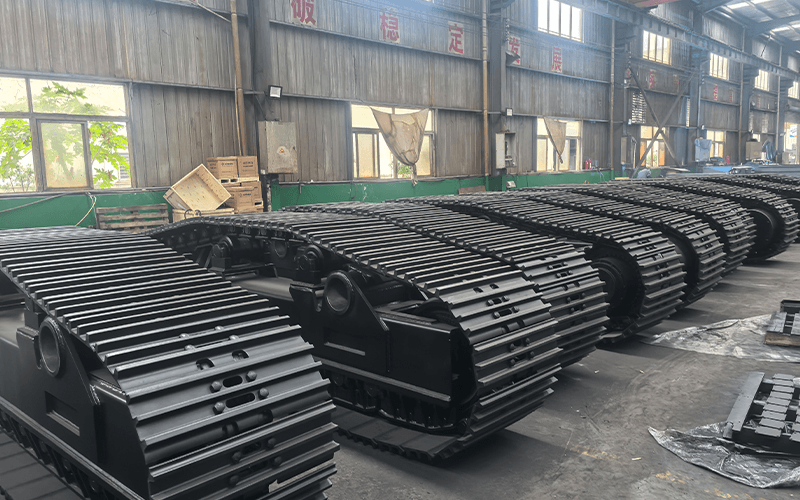

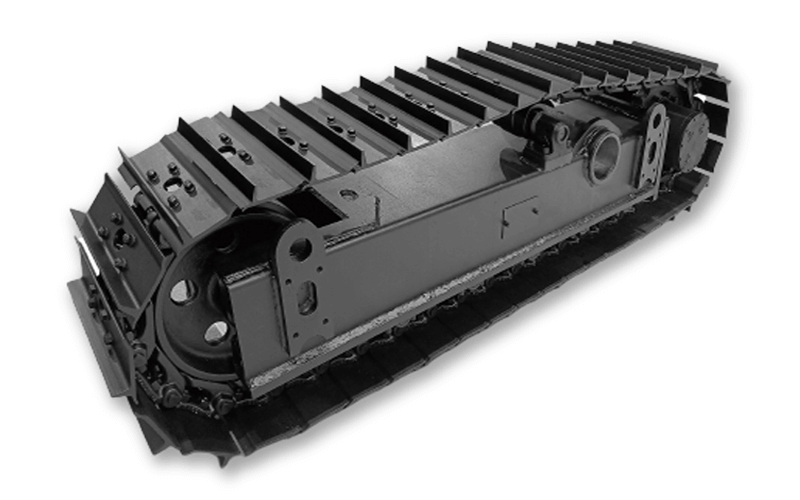

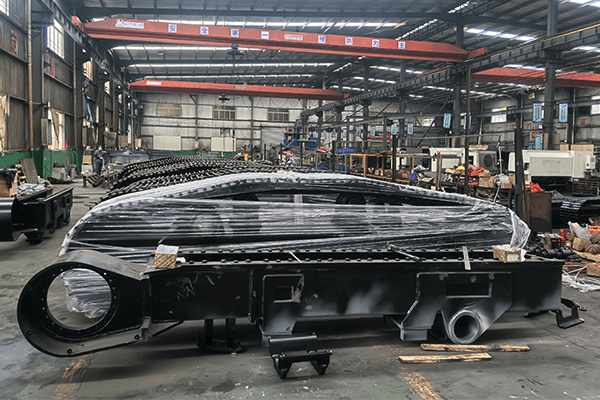

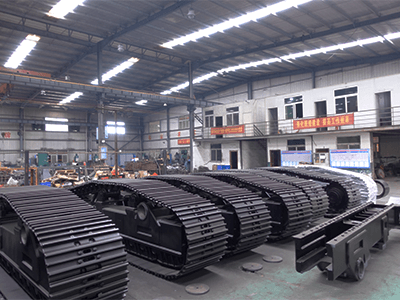

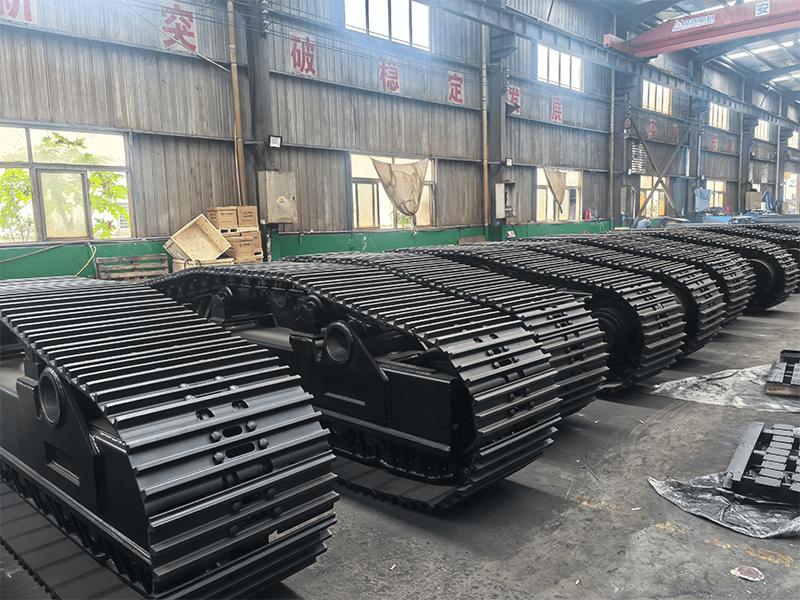

Transform your equipment's capability with complete undercarriage assemblies, engineered for perfect fit and reduced maintenance in the most demanding applications.

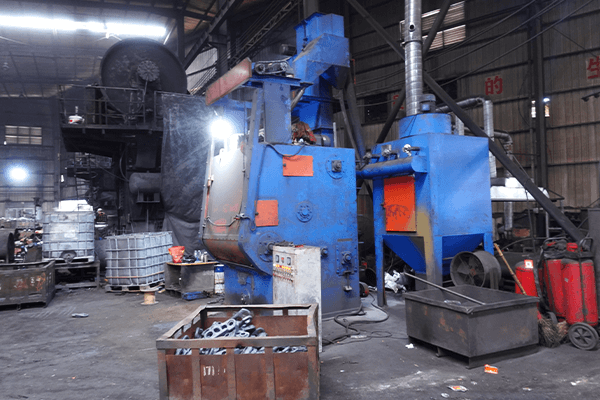

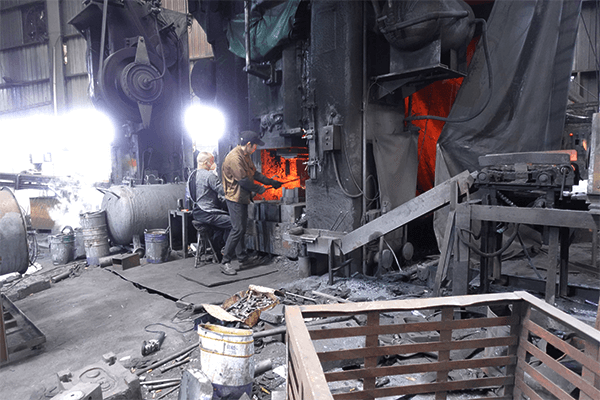

Our advanced manufacturing process ensures premium undercarriage quality through precise machining, heat treatment, surface hardening, and rigorous quality control at every production stage.

Using advanced cutting technology and automated systems, we process premium steel materials with precise specifications. Each component undergoes thorough quality inspection for material composition and structural integrity, ensuring superior undercarriage foundation.

Our sophisticated hydraulic press brakes and forming equipment deliver precise metal shaping with computer-controlled accuracy. Skilled operators maintain strict tolerances throughout the bending process, ensuring perfect profiles for optimal track alignment.

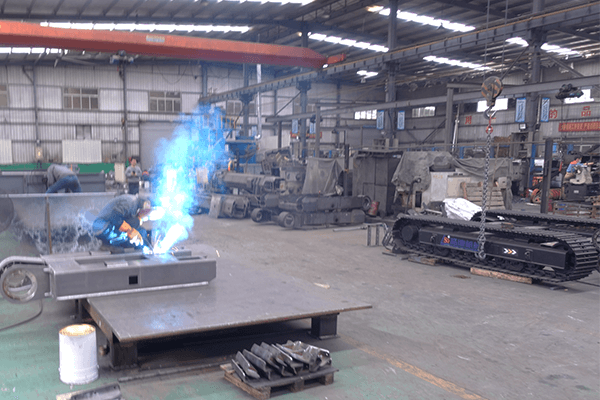

Combining state-of-the-art robotic systems with expert manual techniques, our welding process ensures superior joint strength under strictly controlled conditions. Comprehensive quality testing guarantees optimal structural integrity for demanding applications.

Our advanced machining centers operate with micron-level precision, delivering exact dimensional accuracy and superior surface finishes. Experienced machinists ensure perfect component fit through carefully programmed operations and systematic quality verification.

Following thorough surface preparation, our automated spray system applies high-performance industrial coatings with precise control. Environmental-friendly paint systems and controlled curing ensure superior protection against corrosion and wear.

Expert technicians integrate precision-manufactured components using specialized tools and comprehensive testing protocols. Systematic quality checks verify proper alignment, clearances, and functionality, ensuring reliable performance in every undercarriage system.

Experience seamless undercarriage customization as our experts guide you from technical consultation through precision manufacturing, delivering solutions perfectly matched to your equipment specifications.

Through detailed discussions and equipment analysis, our expert team works closely with you to understand your specific requirements, operating conditions, and performance expectations, ensuring we capture every crucial detail for optimal undercarriage customization.

Our engineering team conducts comprehensive technical analysis, combining industry expertise with advanced design principles to develop customized solutions. We review all specifications and performance parameters to ensure perfect alignment with your equipment requirements.

Following thorough technical assessment, we provide transparent pricing and detailed timeline proposals. Our team collaborates with you to finalize specifications and requirements, ensuring complete understanding and agreement before proceeding to production.

Our production team meticulously coordinates material procurement, resource allocation, and manufacturing schedules. We establish efficient workflows while maintaining strict quality standards, ensuring smooth production process from start to finish.

Utilizing state-of-the-art manufacturing technology and comprehensive quality control protocols, we produce your custom components with precision. Each part undergoes systematic inspection and testing to guarantee superior quality and performance.

We coordinate efficient delivery logistics and provide detailed documentation for your custom components. Our dedicated after-sales team ensures continuous technical support and assistance, maintaining optimal performance of your undercarriage system.

Spanning 10,000 square meters, our modern manufacturing facility integrates advanced production equipment, automated systems, and comprehensive quality control stations for maximum operational efficiency.

Our factory features state-of-the-art machinery, enhancing production efficiency and ensuring the highest quality in undercarriage component manufacturing.

Stringent quality control measures are implemented throughout production, guaranteeing that each component meets our rigorous standards for reliability.

Organized workshops enable our operators efficiently manufacture undercarriage components, ensuring streamlined workflows and timely order fulfillment.

The technical development team innovates new designs and solutions, staying ahead of industry trends and meeting evolving customer needs.

Efficient warehouse management ensures optimal storage and inventory control for quick retrieval of materials and timely delivery of finished products.

Our quality testing facility rigorously assesses undercarriage component performance and durability, ensuring all products meet our strict reliability standards.

The assembly line integrates components into complete undercarriage systems, with skilled technicians ensuring precision and quality in every assembly.

Our logistics hub coordinates shipping operations, optimizing routes and tracking shipments for reliable, timely delivery to our valued customers.

WHY PARTS combines advanced technology and quality manufacturing with dedicated support to deliver tailored undercarriage solutions that exceed your expectations, ensuring your equipment runs smoothly and efficiently.

We ensure superior performance through premium materials, advanced manufacturing, and comprehensive quality control in every component produced.

Our decades of industry expertise and skilled technical team guarantee reliable track parts solutions for all your undercarriage requirements.

We prioritize your needs through personalized service, clear communication, and dedicated support throughout every project phase.

Our customized undercarriage solutions are precisely engineered to match your specific equipment requirements and operating conditions.

Advanced manufacturing equipment and automated systems ensure precise production and consistent quality, meeting the highest industry standards.

Our continuous investment in track parts research and development delivers cutting-edge solutions that enhance undercarriage performance and durability.

From initial technical consultation to after-sales customer support, we provide complete service coverage throughout your undercarriage product's lifecycle.

Our long-standing partnerships and satisfied global clients demonstrate our commitment to excellence in undercarriage solutions, ensuring your equipment runs smoothly.

With decades of industry experience, our dedicated team focuses on delivering premium track machinery undercarriage parts through advanced manufacturing techniques and rigorous quality control processes.

At WHY PARTS, we specialize in providing top-quality undercarriage solutions for construction and mining equipment, drawing on decades of experience in the industry to ensure our products meet the highest standards of durability and performance for our clients.

Committed to customer satisfaction, we strive to build lasting relationships by offering exceptional support and personalized service, guiding our clients from product selection through installation and beyond to ensure optimal performance of their equipment in demanding conditions.

Decades of industry experience ensuring reliable undercarriage solutions.

Advanced manufacturing and quality control for superior product performance.

Customer-focused service providing tailored support for every client's needs.

Our Frequently Asked Questions section is designed to help you quickly find the information you need, whether it's about customization options, product specifications, pricing, or shipping details.

Read our customer testimonials to learn how WHY PARTS delivers quality undercarriage solutions and exceptional customization service, enhancing client relationships and equipment performance.

We rely heavily on our machinery to deliver projects on time. Since we started using WHY PARTS for our undercarriage components, we've seen a remarkable increase in durability and performance. The replacement parts fit perfectly, reducing downtime significantly. Their customer support team is incredibly knowledgeable and always ready to assist, making our procurement process seamless. I can’t recommend them enough!

Allen Womack

Fleet Manager

WHY PARTS is our preferred supplier for undercarriage components. The quality of their products is unparalleled, and our customers consistently appreciate the reliability they've come to expect from us. Their team took the time to understand our custom needs, providing solutions that cater specifically to our rental fleet. The responsiveness and professionalism they demonstrate make working with them a breeze. HIGHLY recommended!

Aaron Murray

Equipment Rental Specialist

Working with WHY PARTS has been a game-changer for Mountainview Excavation. Their team conducted a thorough analysis of our equipment requirements and helped us select the right undercarriage components. We’ve experienced a significant reduction in maintenance costs and downtime. The quality of their products is exceptional; we've had no failures or replacements needed since implementation.

Joseph Siegel

Operations Director

Since integrating WHY PARTS' undercarriage products into our machinery, we’ve noticed a remarkable increase in operational efficiency. Their components are robust, which is essential for the heavy demands of demolition work. The quick turnaround for orders means we rarely experience delays, and we can keep our projects on schedule. Additionally, their attention to after-sales support ensures we have everything we need to succeed.

Nick Davis

Project Supervisor

I’ve worked with many suppliers, but WHY PARTS stands out. Their undercarriage components are not only high-quality but also exceptionally easy to install. We’ve been able to enhance our machinery's performance significantly since switching to their products. Their technical support is second to none, always providing prompt and helpful responses to our questions. It’s a partnership that we highly value.

Ignacio Hathaway

Head Mechanic

WHY PARTS has been instrumental in helping us perfectly match our undercarriage needs with our equipment requirements. The customization options available allowed us to enhance the performance of our fleet significantly. Additionally, the team at WHY PARTS is always proactive and communicative, making the entire procurement process smooth and efficient. I wholeheartedly recommend them to anyone in need of undercarriage solutions.

Lloyd Adair

Procurement Officer

Our customer support team is here to assist you with any questions regarding our products, services, or customization options. Whether you prefer to call, email, or contact form, we look forward to connecting with you and providing the assistance you need.

Licheng District, Quanzhou, Quanzhou, Fujian, China, 362333

+86 156 2876 6357

Monday - Friday: 9:00 AM - 6:00 PM EST

Ready to enhance your machinery performance with our high-quality undercarriage components? Contact us now for a free consultation and discover how our tailored solutions can meet your specific needs.